Blast furnace charge surface management is a key link to ensure uniform charge distribution, smooth gas flow and stable smelting process. Its core goal is to control the order of charge loading, charge angle and charge flow speed to form a reasonable charge surface shape (such as ring, spiral, etc.), thereby optimizing the gas distribu...

Read More

HJKIR infrared solutions with electrical cabinet temperature monitoring system has strong penetration of smoke, and can be used in a wide range of ambient temperature. Offers multiple equipment detection at the same time, saving the detection cost.

Read More

HJKIR application with the integration of infrared (IR) thermal imaging cameras, enhancing quality control and efficiency in welding processes.

Read More

Infrared thermal imaging thermometer solution monitoring continuous casting process non-contact infrared measurement detection technology, HJK infrared thermal imager temperature range work in -20℃~+60℃, temperature measurement range from -20℃ to 2500℃ and with High protection level, can reach IP66, convient modes like optional Electric/automati...

Read More

Efficient infrared thermal imaging camera for blast furnace smelting solution, it can displays the temperature distribution of the material surface in the furnace in real time, with correction algorithm to achieve accurate temperature measurement, match strong environmental adaptability and can be used in harsh environments such as high temperat...

Read More

Infrared thermal imager solution for metallurgy, application sence is Ladle, hjk system establish a surface temperature database for each ladle use cycle ans 360° all-round temperature detection of the package, and 3D schematic diagram shows the temperature field distribution of the package.

Read More

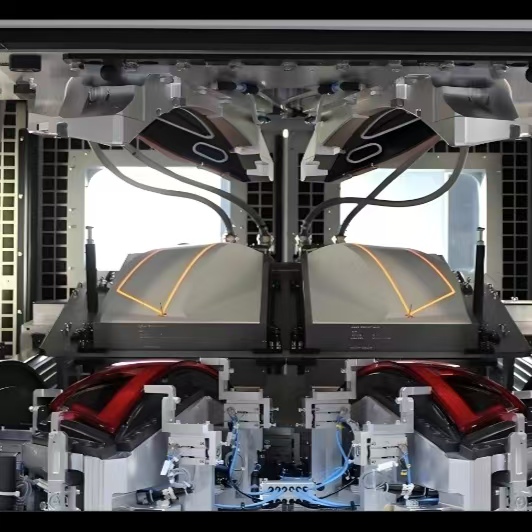

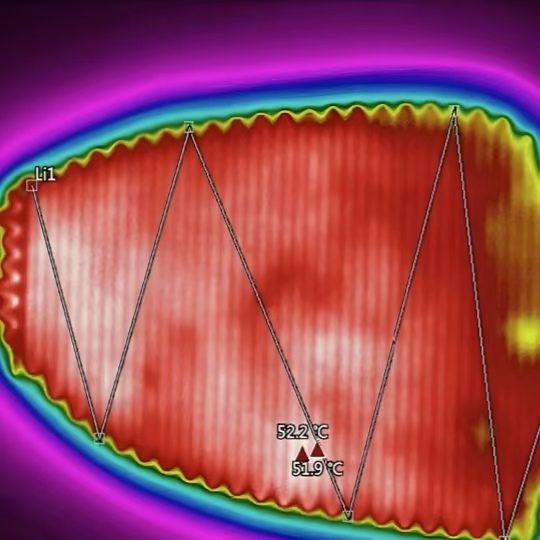

Infrared cameras have become a crucial tool in the automotive industry,infrared devices play a crucial role in monitoring and analyzing heating wires across various industries

Read More

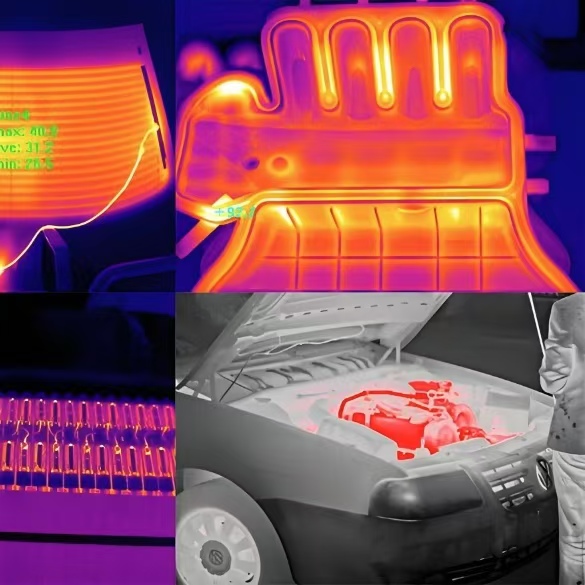

Infrared thermal imaging is used to monitor the temperature distribution across various engine components, such as cylinder walls and exhaust manifolds.Infrared cameras help in detecting faults within the engine by visualizing temperature changes that occur due to mechanical failures.

Read More

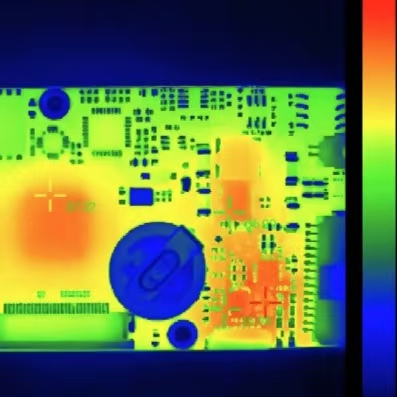

Infrared cameras are essential tools in diagnosing and troubleshooting automotive circuit boards.Integration with Automated Inspection Systems

Read More

Infrared cameras are increasingly valuable in automotive braking systems Infrared devices are also used to assess other components of the braking system

Read More