When working with kilns, proper cooling and maintenance are crucial for safety and efficiency. One critical step is kiln cooling and unloading, often referred to as "kiln unloading" or "kiln discharge." In this process, monitoring temperature and sealing any gaps are key to preventing heat loss and structural damage. Here’s how small...

Read More

Short-wave temperature measurement (ir camera for sale) has the following significant advantages, especially in the fields of industrial detection, remote sensing monitoring, high-temperature measurement, etc.:一. Fast response speed, suitable for dynamic measurement 二、Small environmental interference and high measurement accurac...

Read More

LASER Photonics China 2025: A new chapter of optoelectronic technology innovation and global cooperation From March 11 to 13, 2025, the most influential event in Asia's optoelectronics industry, LASER Photonics China, will be held in Shanghai New International Expo Center. As the flagship exhibition in China's laser, optics and optoe...

Read More

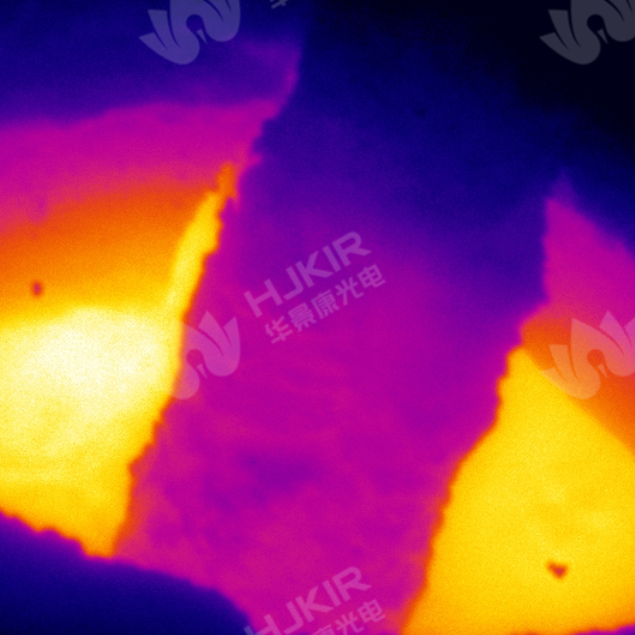

HJKIR infrared solutions with electrical cabinet temperature monitoring system has strong penetration of smoke, and can be used in a wide range of ambient temperature. Offers multiple equipment detection at the same time, saving the detection cost.

Read More

HJKIR application with the integration of infrared (IR) thermal imaging cameras, enhancing quality control and efficiency in welding processes.

Read More

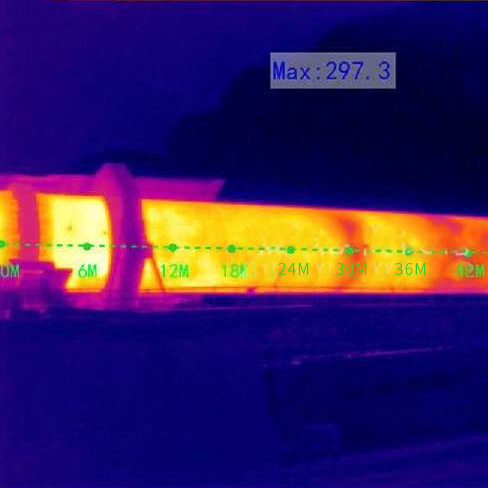

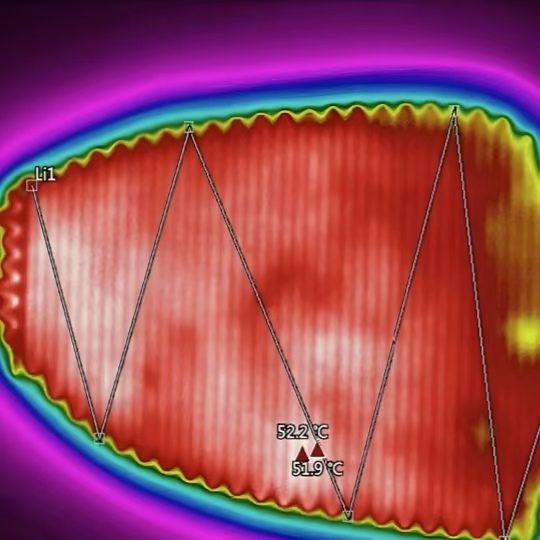

Infrared thermal imaging thermometer solution monitoring continuous casting process non-contact infrared measurement detection technology, HJK infrared thermal imager temperature range work in -20℃~+60℃, temperature measurement range from -20℃ to 2500℃ and with High protection level, can reach IP66, convient modes like optional Electric/automati...

Read More

Efficient infrared thermal imaging camera for blast furnace smelting solution, it can displays the temperature distribution of the material surface in the furnace in real time, with correction algorithm to achieve accurate temperature measurement, match strong environmental adaptability and can be used in harsh environments such as high temperat...

Read More

Infrared thermal imager solution for metallurgy, application sence is Ladle, hjk system establish a surface temperature database for each ladle use cycle ans 360° all-round temperature detection of the package, and 3D schematic diagram shows the temperature field distribution of the package.

Read More

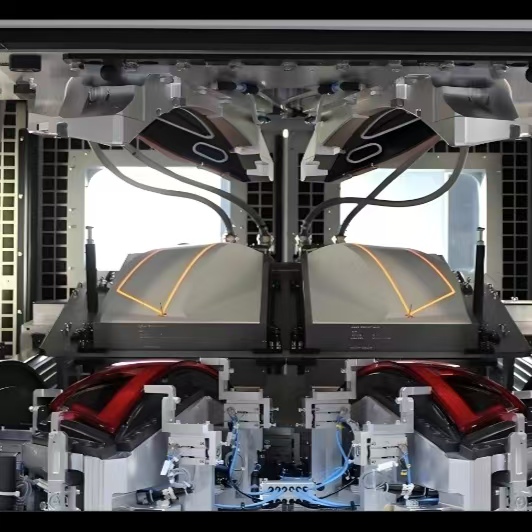

Infrared cameras have become a crucial tool in the automotive industry,infrared devices play a crucial role in monitoring and analyzing heating wires across various industries

Read More